- Proud to be part of your future

- Adapting to change

- The power to do more

- Electric mobility

- Taking care of the future

Proud to be part of your future

The industries are changing faster than they have in the last 100 years. What does this mean for us? We believe major trends like digitalisation, autonomous mobility and sustainability offer great opportunities for us.

Adapting to change

With an entrepreneurial spirit we constantly identify ways to adapt, to make our products better, and to better serve the needs of our customers. New solutions are executed in progressive steps and thoughtful ways, with focus on creating value for all stakeholders – for today and in the future.

The power to do more

Innovation means pushing the boundaries. We listen and interact with our customers and other experts to understand the evolving needs of the industries we serve and those industries we can potentially serve. For example, by participating with carmakers and technology experts in the open innovation platform of ‘Start-up Autobahn’ to help drive our development agenda.

Electric mobility

Motherson does not manufacture engine parts. So the shift towards electric engines and fuel-cell power trains has no negative effect on our business. On the contrary, the rising share of EV sales has the potential to present new opportunities for Motherson.

Taking care of the future

For Motherson, being a trusted partner in the years to come, goes far beyond just economic objectives. With everything we do, we are committed to act sustainably - for the environment, for the communities we serve and for all our stakeholders.

The future has already started

The world of mobility is going through many changes. Connectivity, electrification, autonomous driving and shared mobility are evolutions that will directly affect our customers — and provide opportunities for us to help them shape the future.

Motherson Innovations operates as a global expert team connected with internal and external specialists. Together we aim to support Motherson’s companies adapt to the changes and trends in the markets and to meet the needs of our customers by introducing innovative features, technologies and products that add value to the many business segments we work in.

"We can help them bring the future to life," explains Timo Schwarz, CTO at Motherson Innovations.

The group R&D teams of the different business units are our internal customers. Together with the business partners, our leading technology specialists develop solutions for tomorrow and beyond.

Working together we develop concepts and prototypes that are presented at product and technology exhibitions and at our customers’ tech centres. These can subsequently be further developed into production-ready solutions.

Our ultimate objective is to offer solutions that help our customers provide great products for people all around the globe.

The power to do more

Embracing the future with an open mind, we’re strategically entering new business areas like aerospace, defence and medical — sectors whose demanding engineering requirements create natural synergy with our automotive roots.

“The idea is that we look at the entire range of competencies that Motherson has and explore where we can use these to support customers in adjacent industries,” explains Kunal Bajaj, Head, Aerospace division.

One example is plastic moulding. Our expertise here is increasingly important in the automotive industry, to create entirely new, lightweight interior solutions. But it’s very valuable to the aerospace and medical industries, too.

“We try to keep an open mind,” says Bajaj.

“Sometimes we say we’re a ‘not yet’ company. We’re open to areas where we’re not yet present.”

At Motherson, we’re not just betting on new technologies. “It’s a matter of staying open to what’s happening around us and responding quickly to the evolving demands of our current and future customers.”

The future has already started - Electric Mobility

Over the past few years, Electric Vehicles (EVs) have received increasing attention from car buyers, carmakers and regulators across the world. Electrification is not just happening in light vehicles but also in trucks and two-wheelers. For truck and bus manufacturers, this is a moment of change as well.

With our ever-expanding global presence, we are well-placed to support our customers in the trend towards electrification. This will provide new opportunities for us.

The drive towards electrification is accompanied by a demand for further decreasing the weight of vehicles. To support this, Motherson is developing new materials for instrument panels that have the same strength but are lighter than what is currently available. In addition, we are developing a range of new materials for aesthetic parts such as new finishes and lighting.

To reduce fuel consumption, our Vision Systems and Modules & Polymer Products divisions are working on optimising the aerodynamics of all our parts. For our Wiring Harness division, EVs offer opportunities in the area of high-voltage cable systems as well as a new generation of power-management control systems. The trend towards EVs creates demand for solutions in areas such as charging networks and battery recycling.

Our current order book shows strong interest in our customers' EV models. In addition, the trend towards electrification offers new opportunities in exteriors, interiors, wiring and infrastructure. Motherson is well-positioned to create value for customers in all of these areas.

Taking care of the future of our planet

As an organization, Motherson has always strived to develop the seed of sustainability and care for the environment in it’s operations and in the lives of all its employees.

Motherson believes it has a moral obligation to do everything in its power to provide safe and healthy working conditions for its employees, customers and suppliers, while minimizing the environmental impact.

Focusing on sustainable operations means we seek to reduce the environmental affects impact of our manufacturing processes, logistics, the supply chain, and our development activities.

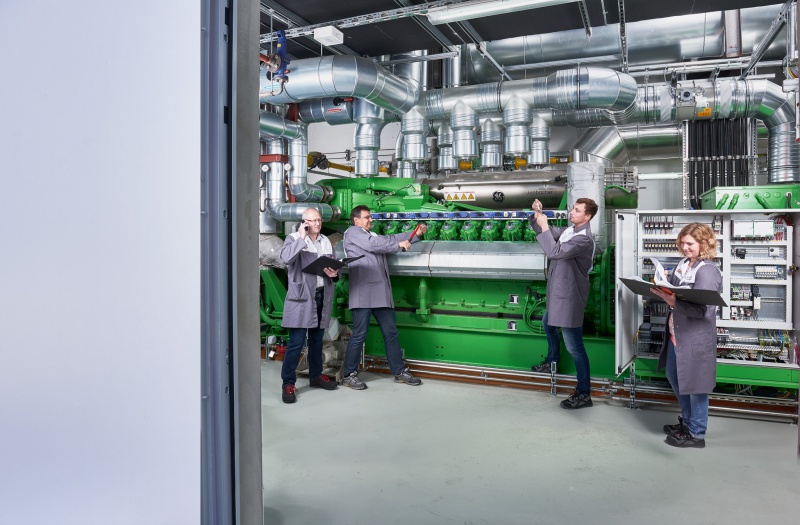

In Neustadt, Germany, for instance, we did so by building an energy facility next to our SMP plant. In the summer, this energy generator helps to cool the machines in the plant. In the winter, when cooling is not needed, it generates energy that we can use to heat the plant and offices.

The whole year round, it generates enough electricity to support around 10% of SMP’s energy needs. That way, we created an energy solution that is better for the environment as well as for the bottom-line.